Advanced Hot Melt Powder Solutions for Modern Manufacturing

Superior Adhesive Performance

DTF hot melt powder demonstrates exceptional viscosity characteristics, enabling strong bonding across diverse substrates. This hot melt adhesive powder maintains consistent adhesive strength even under demanding production conditions. The hot melt powder for heat transfer printing variant offers particularly impressive results on synthetic fabrics.

Rapid Processing Capabilities

Our TPU hot melt powder cures 40% faster than conventional adhesives, significantly boosting production throughput. The hot melt adhesive powder achieves full bonding strength in just 15-30 seconds, while specialized DTF hot melt powder formulations can cure in under 10 seconds for high-speed applications.

Exceptional Thermal Stability

Engineered hot melt powder for heat transfer printing withstands continuous exposure to 150°C without degradation. The TPU hot melt powder maintains structural integrity up to 180°C, making it ideal for automotive and industrial applications where hot melt adhesive powder performance is critical.

Eco-Friendly Composition

All formulations, including DTF hot melt powder, meet stringent REACH and RoHS standards. The hot melt powder for heat transfer printing is 100% free from volatile organic compounds, while our TPU hot melt powder has achieved FDA compliance for food packaging applications.

Multi-Material Compatibility

Versatile hot melt adhesive powder bonds effectively to:

Textiles (natural and synthetic)

Paper and cardboard

Various plastics (PP, PE, PET)

Specialized DTF hot melt powder excels on polyester blends, and hot melt powder for heat transfer printing performs exceptionally on nylon substrates.

Consistent Performance

The TPU hot melt powder maintains reliable adhesion across humidity ranges from 20-90% RH. Our hot melt adhesive powder demonstrates excellent UV resistance, while DTF hot melt powder retains bonding strength through multiple wash cycles.

Technical Specifications:

DTF hot melt powder: 80-120 mesh size

Hot melt adhesive powder: 0.91-0.95 g/cm³ density

Hot melt powder for heat transfer printing: 90-130°C activation temp

TPU hot melt powder: 12-18 MPa tensile strength

Application Guidelines:

For textiles: Use DTF hot melt powder at 110-130°C

For paper products: Apply hot melt adhesive powder at 90-110°C

For plastic bonding: TPU hot melt powder works best at 130-150°C

For transfer printing: Hot melt powder for heat transfer printing activates at 100-120°C

About Us

Specification

Product model | W*L | Melt point(℃) | Wash tempreture(℃) | Heat press tempreture(℃) | Heat press time(s) | Heat press measure(kg) |

MET-1 | 20kg/bag | 105-132 | 40-50 | 125-140 | 10-15 | 1.5-2 |

MET-2 | 20kg/bag | 100-128 | 60 | 105-125 | 10-15 | 1-2 |

MET-3 | 20kg/bag | 100-128 | 60 | 120-140 | 10-15 | 1-2 |

MET-4 | 20kg/bag | 110-120 | 60 | 135-160 | 12-15 | 1-2 |

MET-5 | 20kg/bag | 110-120 | 40 | 130-160 | 10-15 | 1-2 |

Product Description

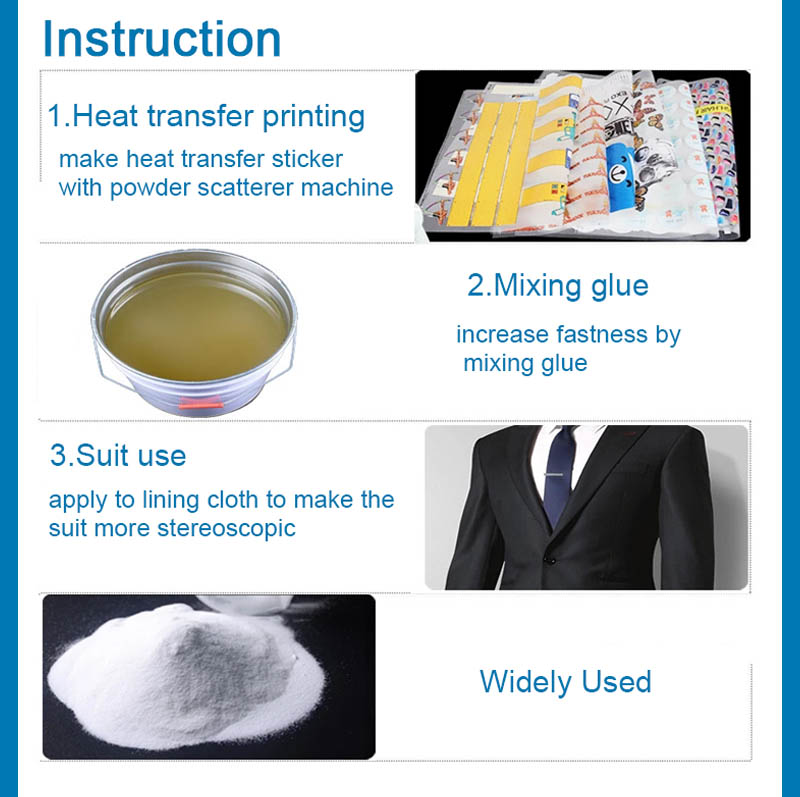

Application

Company Profile

FAQ

Q1:What is the Minimum Order Quantity(MOQ)?

A1:No quantity limited, Sample order or small order is acceptable.

Q2:What is the lead time?(How long will it take to prepare my goods?)

A2:1-2days for sample orders, 3-5 days for bulk orders.(The exact time will be based on the requirements)

Q3:How will you deliver my goods to me?

A3:Normally, we will ship the goods by air, by sea and by express, such as DHL, Fedes, UPS, TNT basing on the needs of different clients.2-3 days via air express, 2-6 days for by air, 20-35 days for by sea

Q4:Can you print my own logo on the products?

A4: Yes ,we can make your own design or put your logo on the product ,please send your design or inquiry to our email ( Whatsapp or Skype ),but also the packing design and other OEM services are available.

Q5:Are you Factory or Trading company&What is your product quality?

A5: We are ink cartridge Factory (Manufacturer),Our raw materials are all purchased from qualified suppliers. And we have very strict QC standard to assure our final products meet your requirements. we 100% testing before ship.

Q6: What is Warranty Policy?

A6: We provide 1 year warranty. During the 1 year warranty, our company will offer you motor and board driver for free if they arefaulty .